November 3rd, 2016

RB Engineering worked with other suppliers to build ‘Torbay’s first electric car.’

The following work was carried out:

Fabricating chassis from drawings supplied by the customer,

Suspension and mounting brackets,

Machining to drive shafts and electric motor assembly.

Please use our Contact page for any enquiries.

See the full story on the Torbay Herald Express website:

http://www.torquayheraldexpress.co.uk/torbay-s-electric-car-handed-far-eastern-client/story-26822074-detail/story.html

Posted in RB News |

Comments Off on Blast To The Past! Torbay’s First Electric Car

April 14th, 2016

CE Marking – A sign you can trust

If you are looking for a fabricating and welding company that you can trust, that is small enough to care but big enough to cope, that has recently achieved level 3 certification in CE Marking, then you need to enlist our services.

Our CE Marking certification is recognition of our outstanding workmanship and quality and opens up so many doors for you to grow your business.

Our certification certificates can be found on the links below:

What is CE Marking?

In its simplest form CE Marking is a way of creating a level playing field for manufactured products across the European Economic Area (EEA). Before CE Marking, each country has its own requirements that a product had to comply with. But now, if your product carries a CE symbol then it can be traded freely across the EEA without having to meet local requirements.

Not all products can carry the CE Mark, only those that meet the standards set in the directives with regards to design safety and administration.

Only companies such as ourselves, who have CE Marking certification, can produce products that carry the CE symbol.

What are the advantages of CE Marking?

- With a CE Marking on your product you can trade safely within any EEA country.

- Claims for damages and liability will be limited as products will be provided with safety instructions for users.

- Products are safer for users.

- Improved product design. As we go through the steps for CE Marking we will do a thorough review of the product which will often highlight innovative solutions.

- Improve production rates. To conform to certain aspects of the directives we will undertake quality assurance tests which can present ways of simplifying the manufacturing process which will reduce costs.

What opportunities does it open?

According to the Office for National Statistics, in 2014 UK exports to EU countries was over £200 billion, and it has been over that 200 mark since 2010.

Having a CE symbol on your product makes it far easier to have a piece of this market. Being solely reliant on the UK market might be ok for now, but for long term growth the more markets that are open to you the better.

The export market could be the next step for your business and we can help you with that.

Why RB Engineering are different

Not all fabricating and welding companies have the ability to self certify compliance with CE directives, but we do. This means that if you want to ship your products to anywhere in the UK or Europe, we can save you time and money.

We have undertaken extensive training so that the goods that we produce for our clients can carry the CE symbol.

Our staff have attained level 3 CE marketing certification which is the highest level for a manufacturer.

We have not only invested heavily in staff training but we also invest in the right equipment for the right job. For example, we have recently purchased a Flow Dynamic IFB abrasive waterjet cutting machine. This means that not only will you be dealing with expert and knowledgeable staff but that they have the tools needed to deliver on big projects.

By using a company that cannot carry out CE Marketing self certification there is the risk that you could end up with an inferior and sub standard product. You will definitely not be able to trade in Europe and there is more chance that you could have an expensive lawsuits filed against you. You will not have any of those problems with us.

The CE Marking that we place on products is not just a symbol to let other countries know that we comply with the directives, but more importantly than that, it is our commitment on quality and service to our clients.

More information on CE Marking can be found on the Government’s Guidance website.

Posted in RB News |

Comments Off on CE Marking Success For Devon Engineering Company

April 14th, 2016

We have recently had some engineering success in Torquay. We received an enquiry through our website regarding a job in Oddicombe, Torquay. The company wanted to use a local engineering company local to work onsite. They choose us as we were ISO9001 and EN1090 accredited.

The work required was to supply various steels for work access and the job needed to completed within a tight deadline.

Our quote was submitted and the customer agreed to go ahead. All materials were purchased for the job.

We ordered all relevant materials which included: Box section- various sizes, angle, flat, all in mild steel.

The work was fabricated to the customers specification.

Various equipment was used such as:

- Plasma cutter

- Welder

- Grinding

The work was completed and sent to the galvanisers. We then then delivered to the customer onsite.

Welding for work access

Completed welding

Posted in RB News |

Comments Off on Engineering success in Torquay

February 29th, 2016

Emergency Breakdowns and Engineering Repairs

We were contacted by our customer as they had an emergency breakdown; their roller had broken up in the plant which caused their processing plant to be shutdown.

The roller was delivered to us to use as a pattern to work from. We had previously carried out similar work so we had all the details on file which enabled us to refer back to. This made the job quicker to carry out as our staff already knew what was required.

Materials involved were: flat strip and tube, guillotined plate, location hubs, shaft machining. Machines involved were: guillotine, spiral section rollers, welders (mag welding) lathes. Painted in our spray shop to the customer’s colours.

The customer was contacting us frequently so the production would be back up and running at their end. This breakdown work was turned around in 1 day.

The customer gave us a fantastic feedback and was very satisfied. RB Engineering works on all their breakdown work as we are very quick on turnaround times. This quick action by RB Engineering saved the company thousands of pounds of potential downtime.

Click for large image

Click for large image

Click for large image

Click for large image

Click for large image

Click for large image

Posted in RB News |

Comments Off on Emergency Breakdowns and Engineering Repairs

February 11th, 2016

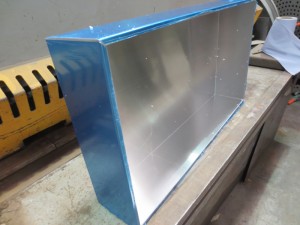

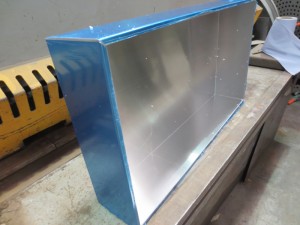

A Devon CNC manufacturing company contacted us with a requirement to produce some prototype aluminium boxes, 1.5 thick and in two different sizes. The customer gave us the drawings (DFX files) so we could take a closer look at the job. We priced the work and gave the customer a quote based on a unit price for 12 with a future order of 200 per year if the job was successful.

Aluminium Boxes

Aluminium Boxes2

The customer confirmed the order and due to the company’s procedures and certificate of conformity requirements we set this up on our ISO9001 system. A purchase order was given to the steel supplier and the job was placed on our production schedule. We have a dedicated member of staff that is qualified to carry out the welding on aluminium products so he was given this production job.

The materials used were 1.5mm aluminium which was cut to size on our guillotine and then press braked and folded to shape. Our qualified welder was then required to weld the sides. On completion the customer came to check the finished boxes and was very pleased with the product. We padded the boxes and within a week we were informed that an order of 190 will be placed over the next year.

Aluminium Boxes3

Aluminium Boxes4

Posted in RB News |

Comments Off on Prototype Aluminium Boxes

January 10th, 2016

At RB Engineering we gain a lot of new work through customer referrals. We believe that our commitment and passion is a key driver in winning new work. A recent job we carried out was no exception and involved a lot of tools and expertise.

We carried out a fabrication job for a haulage company who required new side boards that needed to be lighter, made from aluminium and ensured a great appearance once fitted. The customer was so pleased that we received a new recommendation for a similar job sometime after. The new work was to replace the old, heavy and scruffy looking mild steel sideboards with new shiny aluminium ones. The job required a like for like change but ensuring that the new materials were lighter.

We carried out the required work with 4mm aluminium sheet. Our in house guillotine and folding machines were used in the initial stages of fabrication. Then our qualified welders used both TIG and MIG welding techniques for the different challenges of the job.

As an aside, the major difference between MIG and TIG welding is that one process uses a continuously feeding wire

(MIG) and the other uses long welding rods that are slowly feed into the weld area

(TIG). MIG and TIG welding both use an electric arc to make the weld. TIG welding is more commonly used for your thinner gauge materials. Items that are made with this process are things like kitchen sinks and tool boxes.

We designed the shapes on our CAD software which worked out the bend angle and the materials bend allowance which then meant we could write a programme for our CNC press brake which speeded this process up. Once the parts were folded we then dry fitted all the parts to the lorry and MIG/TIG welded as required.

Our customer required the lorry to be completed as soon as possible as he needed to minimise lorry down time. The customer collected the lorry and was very pleased with the quality of the work.

As you can see we used a variety of skills, tools and processes to complete this job. If you require projects that involve the above please contact us on Newton Abbot 01626 835 951.

Posted in RB News |

Comments Off on Lorry aluminium side boards

January 10th, 2016

Manufacturing of a glass sheet storage rack.

A valued customer required a heavy duty stand for the glass cutting area of their factory unit. We were not supplied any drawings so we went onsite to measure the existing trolley. Our task was to design new ones but to ensure they were stronger and better suited to our customers way of working.

CAD drawings were created from the onsite measurements. We required a box section, heavy duty castors, hardwood profiles and rubber sheet. Each stage of the fabrication was passed through the different areas of our fabrication premises here in Newton Abbot, Devon and some of the equipment used was a chop saw, waterjet cutting machine, profiler, mig welding and our dedicated paint shop facilities.

We delivered the final product to the customer who has since commented on the stability of the fabrication and the ease by which the trolleys can be moved due to the bearing castors.

Posted in RB News |

Comments Off on Glass sheet storage rack

December 16th, 2015

A local manufacturing company contacted us with a requirement to fabricate and install a platform staircase. The platform was needed to allow safe pedestrian access over the conveyors. This was deemed a high risk area to employees who were ducking under the conveyors which was a security and health risk, so these access platforms were designed to create a low risk area.

After meeting and discussing the project with the customer we took the appropriate measurements and checked all heights and clearances before starting. Halfway through the project we met with the customer who carried out a secondary check to ensure all measurements were accurate.

All materials were order through our ISO systems, requiring S355 steel, band saw, punch, guillotine and our qualified welder. The customer also confirmed the colour and type of paint that was to be used. This was 2 pack epoxy. We are one of the few engineering and fabrication companies that have our own dedicated spray booth and this was used to paint the final staircase.

Platform staircase fabrication 1

Platform staircase fabrication 2

Platform staircase fabrication 3

Platform staircase fabrication 4

Our ISO systems and CE Marking accreditation ensures that all our work is of the highest quality. Some advantages of our CE Marking are:

- With a CE Marking on your product you can trade safely within any EEA country.

- Claims for damages and liability will be limited as products will be provided with safety instructions for users.

- Products are safer for users.

- Improved product design. As we go through the steps for CE Marking we will do a thorough review of the product which will often highlight innovative solutions.

- Improve production rates. To conform to certain aspects of the directives we will undertake quality assurance tests which can present ways of simplifying the manufacturing process which will reduce costs.

The work was completed on time and on budget and we installed and checked the platform before leaving the premises. Our customer now benefits from having safe access to machinery.

Our premises are conveniently situated in the Heathfield Industrial Estate of Newton Abbot, Devon and we are experienced with a variety of commercial and industrial fabrication jobs delivered throughout the UK. For more information please contact us on 01626 835 951.

Posted in RB News |

Comments Off on Platform Staircase Fabrication

December 7th, 2015

Outfall/storm grille and ladder for a local civil engineering company.

A customer contacted us about a contract they took on for a local authority which required us to go onsite to measure up for an inspection ladder and culvert intake grille. It was explained to us by the customer that they were required to inspect the culvert internals and monitor the water flow; this was for a new system. A quotation was required based on material, labour and galvanising. The customer gave us a purchase order and told us to go ahead with a time scale of a week.

Materials were used from our stock supply which was: mild steel, bar and tube. Machines used were punch, tube bender and press brake and our qualified welder was required. Once the work was completed we delivered it to the galvanisers for an urgent turn around. We then collected and delivered to the site. Our customers were very grateful for the quick turn around and the quality of the workmanship. The great thing was that we had all the materials available in stock to get this job completed quickly.

If you have any requirements of this nature or would like to talk about a similar project then please contact us today on 01626 835 951.

Storm Grill Fabrication

Storm Grill Fabrication 2

Ladder Fabrication

Ladder Fabrication Newton Abbot

Posted in RB News |

Comments Off on Outfall Storm Grill and Ladder Fabrication

November 27th, 2015

At RB Engineering we are able to provide fire escapes to schools, hotels, leisure centres, domestic and commercial properties to name but a few.

When investing in a fire escape it is essential that you get it right. A fire escape must be safe, fit for purpose and comply with all relevant building regulations. As an accredited Devon based CE Marking Company you can rest assured that we have the experience and expertise to manufacture the best fire escape staircase for your needs.

We can design from single flight domestic fire escapes through to multi floored staircase structures, all of which take careful planning and accurate engineering.

Our recent work for a local customer

Our customer required a fire escape because they had a recently constructed mezzanine floor that only had one entrance staircase and the offices were being used on the mezzanine, so this was urgently required.

Fabrication of Fire Staircase

Fabrication of Fire Staircase

We completed the job in just 4 days and this included the time from fabrication to installation. This then needed to be signed off by the building control. The work fell into EX2 Level for CE marking EN1090. The drawing was supplied by the structural engineer and we used S355 as required by the structural engineer which we had available in stock which gave us the advantage with the turnaround time.

We used a variety of machines and procedures including punch, bandsaw, qualified welding staff with weld procedures. Another satisfied customer!

From a safety point of view it is necessary to ensure that the use of an external escape stairway cannot be prejudiced by smoke and flames issuing from openings (such as windows and doors) in the external wall of the building. Any door opening onto the stairway below the top floor and any door in the external wall beneath the stairway should be self closing and should have a minimum half hour standard of fire resistance.

The route from the foot of the stairway to a final place of safety should be unobstructed and free from vegetation and there may be a requirement to provide both primary and emergency lighting for the whole of the escape route and a suitable stairway enclosure to afford protection from the weather.

Please contact us for advice and guidance.

Posted in RB News |

Comments Off on Staircases for Fire Escapes

November 27th, 2015

Maintenance Stair and Platform

This was designed to enable easy access for maintenance on a production line instead of using ladders. We went to the site and met with the customer to discuss the work in detail. We took measurements, converted our sketch and measurements to a CAD and fabrication drawing. Checks were made by the customer and they confirmed that this work fell into EX2 level CE marking. As a fully accredited CE Marking company we are used to dealing with such demands and could easily accommodate the job. We had previously carried out similar work to a high standard. This job took 2 weeks to complete and was fully installed and checked onsite.

The materials we ordered came through our ISO systems, S355 steel was required, bandsaw, punch, guillotine and our qualified welder. The customer came halfway through the build to check the heights and clearances and to inspect the quality of the work. In addition to the manufacture of the stair and platform the customer also confirmed the colour of the paint and paint type. This was 2 pack epoxy. Our dedicated spray booth was required for this work.

For this one job everything was done in our Newton Abbot facility. If you require similar work then look no further than RB Engineering.

Steel Stair and Platform

Steel Stair and Platform

Posted in RB News |

Comments Off on Steel Manufacturing of Maintenance Stair & Platform

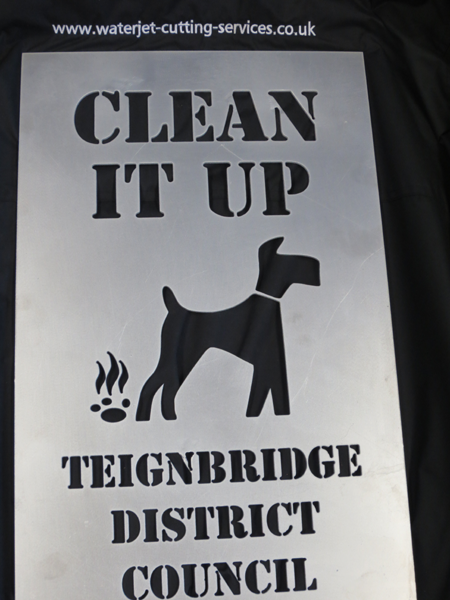

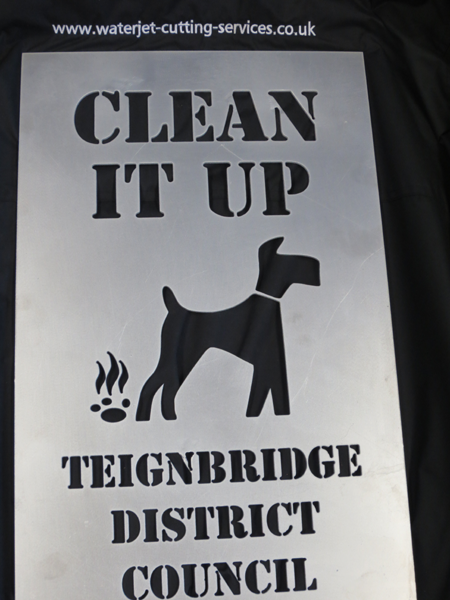

November 23rd, 2015

A local signage company contacted us via Teignbridge council to produce a stencil for a “clean it up” campaign. The customer supplied his own drawing for this urgently required job. The materials were held in stock and our state of the art waterjet machine was put to work. We used 3mm stainless steel for the signs and because the waterjet cutting process does scorch the metal the results were a clean and precise sign. The local council were pleased to be able to use this stencil time and time again to get the message across in local areas such as playgrounds. They were also impressed with how quick the job was completed.

Waterjet Cutting Stencil

Waterjet Cutting Stencil – Finished

Posted in RB News |

Comments Off on Waterjet Cutting For A Stencil

November 20th, 2015

For this job we had to supply 4 stainless steel mixing tanks. The time scale was 3 weeks and it took 2 staff members to complete. The drawing was supplied by the customer to work from but we had already made similar but smaller tanks. The tanks were 23000 litres.

We had our draftsman work out how much stainless sheet was required. Detailed fabrication drawings were required for this work. Low energy motors were also required and mixing paddles as per customer specification. Materials and processes used were 316 stainless, plate roller, section rollers, guillotine and qualified fabricator.

The finished articles were delivered to the site, placed in position and bolted down. The relevant pipework was then connected. The work was carried out in the allocated time. We were able to make significant gains in efficiency and consumption as these motors run 24/7.

Posted in RB News |

Comments Off on Fabrication of Stainless Steel Mixing Tanks

October 5th, 2015

Agricultural Machinery Repairs From RB Engineering

This job required a complete refurbishment of an agricultural topper which was disintegrated, which required major work.

The local farmer needed the job to be done urgently, as a new topper would be more expensive to buy and would take to long for delivery.

Various parts on the topper required waterjet cutting, we produced a drawing file for this work and it also required 4mm and 6mm steel plate. This then meant we needed to organise various parts to be sent for galvanising. We used the old topper as a template to work from; we have never refurbished a topper part before but have carried out various other jobs for local farmers in the past.

4mm and 6mm materials were ordered and the job was placed on production. Our qualified staff were given the job, equipment used was: guillotine, pressed blade and calibrated welder. Parts were sent away to the galvanisers and once they were back fitted. The client was contacted to check the job over; we then decided to use our in-house spray shop for a complete John Deere green paint work to be carried out.

From start to finish the job took a total of 2.5 weeks. Our customer was happy as this meant he could go back and work on his fields quicker than if he had took another option. Saving him the time and money was a big advantage for him.

Agricultural Topper Repair – Before

Agricultural Topper Repair – After

Posted in RB News |

Comments Off on Agricultural Machinery Repairs

September 23rd, 2015

Waterjet Cutting Thick Nylon – We were approached by a long standing customer requesting specialist watejet cutting of a 50 mm thick nylon. Using waterjet cutting is idea for this type of material becuase it does not burn or mark the surface of the item. We were supplied with a CAD drawing in DXF format with a 2 week timescale to complete the job.

The CAD drawing was checked by our team and we then ordered the nylon material from our preferred supplier. The waterjet cutting machine was setup and configured for the job and it was completed in 1 ½ hours to complete.

The final outcome was that the job was completed within the quoted timescale. From the initial enquiry to delivery, we were able to complete this order for our customer in under a week. the customer to enquiry to delivery was completed within 1 week and was delivered to the client within the required time date.

Waterjet Cutting of Nylon 1

Waterjet Cutting of Nylon 2

Posted in RB News |

Comments Off on Waterjet Cutting Thick Nylon

June 2nd, 2015

The year 2001 is when the family run business of RB Engineering in Newton Abbot began its journey. The company has gone from strength to strength since those early days, building up a range of clients such as Paignton Zoo, Sibelco, Plymouth University, LMS Highways and Ceramic Tile to name but a few.

The engineering team at RB Engineering in Newton Abbot are fully qualified and dedicated to providing the best possible service. Client communication is an important factor in every job that is undertaken and regular meeting and discussions are held to ensure that the work is done specifically to the client’s requirements.

RB Engineering in Newton Abbot has invested in high quality machinery in order to offer a wide range of services. Here are some of the services offered by the company:

- Steel Fabrication

- Water Jet Cutting

- Marine Fabrication

- Welding

- Vehicle body repairs

- Vehicle repairs

- General Engineering Work

Some of the stainless steel fabrication work undertaken by RB Engineering include: stainless steel storage tanks, stair cases, mezzanine flooring and steel buildings.

With the facilities and skills to manufacture pulpits, push pits and deck furniture to specification, RB Engineering can manufacture bespoke bow rollers and a large array of other marine equipment from scratch.

RB Engineering offers all vehicle repairs from servicing to major smashed vehicle work. Their commercial vehicle body shop is located opposite the main workshop at Heathfield Industrial Estate, Newton Abbot. Full vehicle servicing is also available at the Commercial Vehicle Body Shop. With 35 years of experience you can expect a first class repair service from the team.

If you require some fabrication work or your car is in need of repair, make sure you contact the best. Telephone RB Engineering in Newton Abbot on: 01626 835951 and let the experts help you.

Roll Cage Design

Mild Steel Fabrication

Steel Fabrication Paignton Zoo

Steel Fabrication Paignton Zoo Wetlands Project

Tags: Commercial Vehicle Repairs, Manufacture, Marine Fabrication, metal fabrication, Newton Abbot, RB Engineering, Steel Fabrication, water jet cutting, Welding

Posted in RB News |

Comments Off on RB Engineering in Newton Abbot

May 18th, 2015

An existing customer requiring Steel Fabrication of Trolleys contacted the team at RB Engineering to discuss the making of 20 new trolleys for their production painting area. As the work that requested was a standard fabrication job any of the qualified staff could do the work.

This type of work had been done before so the team used the same suppliers for the castors and the correct grade of steel which was S275. The trolleys would be used in the clients paint baking area so it was essential that they could handle 60 degrees of heat. High temperature paint was also required.

Drawings were not used for this work as the client brought in an original trolley for the team to look at and take notes.

Old Production Trolleys

Trolleys manufacture Newton Abbot

A qualified member of staff manufactured the trolleys in the RB Engineering workshop and they were then painted in the spray booth.

There was no set delivery time in place but RB Engineering work to a production schedule, this system is generally 2 weeks.

When the work was completed and delivered to the client, they were extremely happy with the end result and they found the trolleys a great help.

RB Engineering offers a wide range of Fabrication Services such as: Coded Welding, Tube and Section Rolling, Cutting, Folding Notching and Welding, Fabrications in Aluminium, Stainless Steel and Mild Steel, Tube and Section Rolling, Tube Notching. Clients can expert 1st class workmanship from fully qualified engineers.

Take a look at the RB Engineering website and see how they can help you. The many services include: Precision Water Jet Cutting, Marine Fabrication, Rollers for Conveyors and Motor Vehicle Repairs.

The team also carry out welding repairs and general engineering, onsite maintenance and breakdown repairs for the manufacturing industry.

To contact RB Engineering you can use the contact form on the company website or call 01626 835951. If you have any questions or queries the staff will be only too happy to help you, so please don’t hesitate to get in touch.

Tags: Aluminium, British, castors, Ceramic Tile, Coded Welding, Conveyors, cutting, Fabrication, Folding, Marine Fabrication, Mild Steel, Motor Vehicle, Notching, painting, Repairs, Rollers, Section Rolling, Stainless Steel, trolleys, Tube

Posted in RB News |

Comments Off on Steel Fabrication of Trolleys

May 11th, 2015

Local agricultural engineer James Trout contacted RB Engineering about an urgent job that he required. A large tractor axle assembly part required immediate facing off on a lathe.

The axle assembly measured 900mm in diameter and our Colchester lathe was perfect for this type of work. No drawings were required but James Trout had requested that we remove the least amount of material as possible. The axle assembly is part of the tractors breaking system and our experienced engineers removed the least amount of material. If too much material was removed there would be too much travel in the hydraulic breaking system.

Engineering in Newton Abbot

The part was badly worn and there was heat build-up so before the work was started our experienced engineers die penetrated the part to ensure that there were no underlying cracks that would cause issues at a later date.

The work was completed within 3 hours of the part being delivered to RB Engineering. James Trout was very happy with the result as his client downtime was reduced greatly. If James Trout had ordered a new part from the manufacturer it would have taken 5 – 7 days for delivery and he could not afford to wait that long.

RB Engineering staff carries out large machine work on a regular basis. Experienced engineers are at hand to provide a first class professional service. They work hand in hand with their clients to ensure the best possible end result with each job they undertake.

If you require engineering work such as fabrication, welding, lathe machining then take a look round the RB Engineering website to see how RB Engineering can be of assistance. If you don’t see what you’re looking for, call the office on 01626 835951 and find out if our experienced engineers can help you. We look forward to hearing from you.

Lathe work at RB Engineering

Machining in Newton Abbot

Tags: axle assembly, Colchester lathe, machining, RB Engineering

Posted in RB News |

Comments Off on James Trout – Case Study

April 27th, 2015

Tig Welding, Guillotining and Press Brake

In this article we will explore Newton Abbot Engineering Case Study which included using tig welding, Guillotining and Press Brake work.

Our client had recently purchased several new Lorries as part of the expansion of his locally owned line marking business. After contacting RB Engineering he visited the workshop to discuss the work that was required.

Fitting of the new fabricated tank

Materials used by the team for this work was, mild steel plate and various hydraulic fittings.

The work entailed, fabricating and installing hydraulic tanks, fabricating and mounting manifolds for Gas Supply Compressors, fitting various pipe associated brackets and modification of aluminium fuel tanks.

In 4 days’ time the Lorries would be needed for contract work and the deadline was set for this time scale.

The measurements for the hydraulic tank had to be precise to ensure that the tank was not affected when the cab was tipped. Pipe sizes for the hydraulic flow between the tank and the pump needed to be worked out correctly. The tank has to fit into a specific space and hold the 250 litres of oil with allowances for expansion.

On completion of the fabrication work tests were carried out including pressure testing the tank to 8psi and no leaks were found. The tank was then painted with a coat of coast etch primer and two coats of top white coat.

The finished items were then taken to the client’s premises where the tank was fitted and the hydraulic pump was bolted on. All of the hoses were connected and the tank was filled with hydraulic oil. A test run was successfully completed.

The deadline was met and the client was able to fulfil his contracts on time.

The client had visited the workshop daily to witness the progress of the work and discuss the fittings of all the parts. He was more than happy with the end results and has since become one of RB Engineering’s top customers.

This case study is typical of the kind of work RB Engineering do. If you would like further information, please feel free to call the workshop on Tel: 01626 865951.

Fitting new pipes

Lorry Hydraulics

Tags: gas supply, hydraulic tanks, LMS highways, mounting manifolds, Newton Abbot Engineering

Posted in RB News |

Comments Off on Tig Welding, Guillotining and Press Brake

April 20th, 2015

RB Engineering received a request from Plymouth University that would require their skills of Stainless Steel Fabrication Devon. The university were holding an award ceremony and asked the team if they could design and manufacture awards for their up and coming award ceremony.

Stainless Steel Fabrication Plymouth University

This would be a new challenge for the team at RB Engineering as they had not undertaken this type of work before.

Meetings were arranged with the client who produced drawings. RB Engineering would supply the materials and do all aspects of the work required for the stainless steel fabrication Devon, the team were also responsible for arranging a local engraver. The work schedule was 1 week due to the engravers own schedule being busy.

The leaf design was transferred into design software and then emailed to the client for approval. Once the design was approved it was then put into the water jet machine to enable cutting to begin. When the cutting was complete the parts were measured for directional accuracy and then taken to the engravers by one of the RB Engineering team who also collected them when the engraving was complete.

Back in the workshop all parts were folded on the press brake. Next was to machine all bosses, these had to be a sliding fit on the main stand, and then pressed into the leaf. Trim caps were also machined.

The RB Engineering team then fabricated the main holding stand from stales steel tube and place. The centre tube was mirror polished stainless steel and the base plate was brushed stainless steel. The brush effect was done with the in house polishing machine. The parts were then test fitted and cleaned ready for the customer to approve the finished product.

The customer was happy with the product and the awards were presented at the university ceremony.

For RB Engineering this was a one off project, but since undertaking this stainless steel fabrication Devon, they have had numerous inquiries.

Stainless Steel Fabrication

Stainless Steel Fabrication

Tags: awards, base place, brushed stainless steel, engravers, Plymouth University, polished stainless steel, RB Engineering, Stainless Steel Fabrication Devon

Posted in RB News |

Comments Off on Stainless Steel Fabrication Devon

April 10th, 2015

It took 19 months over 16,229 miles (26,232 km) in an attempt to break the record for running round the world unassisted. As he completes his amazing challenge, crowds gathered round to welcome him home in Haytor car park where his journey began.

RB Engineering are proud to have sponsored Kevin and look forward to hearing tales of his around the world ultramarathon.

RB Engineering Support Kevin Carr

Well done Kevin!!

Where to Donate

Kevin’s challenge was to raise money for the charity SANE and the British Red Cross.

If you would like to find out about Kevin’s journey you check out his website here: http://hardwayround.com/ You can also make a donation on the site if you wish to.

Kevin Carr home at last

Ultramarathon Runner Kevin Carr

Tags: Haytor, Kevin Carr, RB Engineering, round the world, sponsored, Ultramarathon

Posted in RB News |

Comments Off on Kevin Carr Completes His Amazing Challenge

April 9th, 2015

With enormous pride RB Engineering Supports Ultramarathon Runner

When ultramarathon runner Kevin Carr made the decision to break the world record for running around the world unassisted, he approached RB Engineering and asked for their support with his quest. Kevin’s aim was to tow a small lightweight portable trailer which would carry his equipment.

RB Engineering Supports Ultramarathon runner

Kevin had designed the trailer to cater for all his needs and he produced drawing which RB Engineering worked on with him.

The trailer had to be made from a aluminium frame structure and carbon fibre Panelling, and low friction wheels, which were supplied by Kevin, a brake assembly and carbon fibre handles.

Kevin visited the RB Engineering workshop regularly while the parts were being produced and this enabled him to check for any issues that would arise. Issues were overcome by altering the thickness of materials and removing any weight where there wasn’t a strength issue.

Some of the tools used in the production of the trailer included, water jet cutting, ali fabrication, tig work, press break work and manual turning and milling.

The time scale for the project was 2 weeks and the trailer had to be tested.

Once the project was complete Kevin picked up the trailer and took it for a test. It was good to go and in July 2013 Kevin left Haytor car park to being his ultramarathon.

24 hours later RB Engineering received a phone call from Kevin, he told them that there were slight issues with the trailer due to the amount of bottled water he was carrying. The trailers balance was back heavy when it was being towed. To resolve this issue RB Engineering fabricated an aluminium water bottle holder which was to be bolted to the front of the trailer to keep it balanced while it was being towed.

Plans were made to meet Kevin at Dorchester which was on his route and the aluminium water bottle was fixed into place.

One week into Kevin’s run he contacted RB Engineering before he was due to go to France. He had realised that he would need to carry more water so he asked if RB Engineering would meet him at Dover to transport a buggy for the next part of his journey. The trailer was taken back the workshop where it was to be altered from a towing position to a push position.

The alteration required moving the ale from the centre to the rear of the trailer and adding a third wheel at the front. In the absence of Kevin to test the trailer one of the RB Engineering team who was a similar build as Kevin tested the trailer.

When all the tests were complete the trailer was packed up and shipped to Australia ready for the next part of Kevin’s ultramarathon.

Kevin’s world record breaking attempt is has now been completed and you can see his journey by visiting http://bit.ly/1aNGSPP

RB Engineering are proud to have been involved in this one off job and look forward to Kevin returning and hearing about all his adventures during his record breaking Ultramarathon.

Anne Widdecombe with Kevin Carr

Tags: aluminium structure, carbon fibre, Kevin Carr, low friction wheels, Panelling, trailer, Ultramarathon Runner, world record

Posted in RB News |

Comments Off on RB Engineering Supports Ultramarathon Runner

April 6th, 2015

The RB Engineering team are highly skilled in Commercial Vehicle Spraying Newton Abbot. From small dents to major accidents, the team have the expertise to make your commercial vehicle look as good as new.

Services for vehicle repairs are centralised in the one stop shop which is fully equipped to deal with vehicle repairs is situated near the RB Engineering workshop in Heathfield Industrial Estate, Newton Abbot. Within this area there are facilities to provide a variety of repair services for all types of vehicle repair.

Projects that are carried out by the team range from small metal work refurbishment to major body repairs.

Commercial vehicles play a significant part in portraying the identity of a business and the team at RB Engineering can provide a 1st class quality service for your commercial vehicle spraying requirements. This family run business certainly has the knowledge and experience to provide a high quality friendly service to its customers.

RB Engineering have a lot to offer regular and potential customers. If you are looking to have your commercial vehicle or vehicles sprayed here are some reasons why you should choose this RB Engineering:

• 35 years of experience

• Experts

• Professional

• High quality workmanship

• Reliability

• Honesty

• Friendly

• Engineers take pride in their work

• Convenient One stop shop for all vehicle repairs

If you are looking to have a professional commercial vehicle spraying service for your company vehicle or vehicles, RB Engineering is the company to help.

For further information and details about all of the services provided by RB Engineering contact Jeff on one of the following numbers:

Tel: 01626 835951 Mobile: 07718 576659

Jeff will be happy to hear from you.

Commercial Vehicle Spraying Newton Abbot, RB Engineering is the company to provide a 1st class high quality finish. Give them a call today!

Commercial vehicle spraying Newton Abbot

- Commercial Vehicle Spraying Newton Abbot

Tags: Accident Repair, Brakes, Clutches, Commercial Vehicle Repairs, commercial vehicle spraying, Gear Boxes, Newton Abbot

Posted in RB News |

Comments Off on Commercial Vehicle Spraying Newton Abbot

March 30th, 2015

Did you know that RB Engineering offer a friendly, first class service in Commercial Vehicle Repairs Newton Abbot? Yes, it’s true, you can have your vehicle repaired in the premises that are conveniently located across from the RB Engineering Workshop in the Heathfield Industrial Estate of Newton Abbot.

RB Engineering offer services for commercial vehicle repair Newton Abbot to the general public, trade companies, commercial companies and lease companies. The services range from safety inspections to a full service for small to light vehicles.

A list of services for Body repairs and Vehicle repairs include:

Body Repairs

- Lease hire returns

- Fabrication work

- High quality re-sprays

- Custom re-sprays

- Full accident damage repair

- Minor damage rectification

- Internal refit

- Insurance repair

- Scratches and minor chips

- Major accident repairs

- Smart Repair

Vehicle Repairs

- Clutches

- Gear Boxes

- Brakes

- MOT preparation and presentation

- Tyre Changing facility

- Full steam cleaning service

- Major repairs including accident damage

- Servicing for any type of commercial vehicle

Along with the above services RB Engineering can also offer:

- A courtesy vehicle (must be insured by the client) by arrangement.

- Repair and maintenance contract on request.

- Full baking facilities to carry out repairs and servicing

- A one stop shop for your commercial vehicle repairs.

With over 35 years of experience the team at RB Engineering certainly have sound knowledge of commercial vehicle repair.

This family run business was formed in 2001 and has gone from strength to strength. Offering a wide range of services including: Fabrication and welding. RB Engineering take pride in the services the projects they work on and all work is carried out to a high standard in a friendly manner.

Your vehicle will be in good hands with the team at RB Engineering who will provide you with the very best of service for Commercial Vehicle Repair Newton Abbot.

If you want further information give Jeff a call now!! Contact: Jeff Robson at RB Engineering on one of the following contact numbers:

Telephone: 01626 835951

Mobile: 07718 576659

Jeff will be happy to hear from you.

RB Engineering for Commercial Vehicle Repair Newton Abbot, a first-class company that will help keep your business on the road, safely.

Commercial Vehicle Repairs

Commercial Vehicle Repairs Newton Abbot

Commercial Vehicle Repair Newton Abbot

Vehicle Repair s Newton Abbot

Tags: Accident Repair, Brakes, Clutches, Commercial Vehicle Repairs, fabrication work, Gear Boxes, Insurance Repair, Internal Refit, Lease hire, MOT preparation, Newton Abbot, re-spray, Workshorp

Posted in RB News |

Comments Off on Commercial Vehicle Repairs Newton Abbot

March 23rd, 2015

RB Engineering offer CNC Milling Services Devon to clients. Using this service they were able to fabricate mixer shaft spacers for one of their clients.

10 mixer spacers were requested by the client that were to be fabricated from 40mm mild steel plate to an accuracy of 0.05mm. A CAD drawing was made to produce a profile of the 40mm plate. The profile was then transferred to the water jet to produce the parts required for the mixer shaft spacers.

A fixture to hold the parts onto the CNC milling machine was fabricated. Once on the milling machine the location dowels were drilled and tapped. The team then turned and screw cut the location dowels on the lathe and assembled dowels into shaft spacer. The edges were then deburred to finish off the product.

All sections of the work was checked in line with ISO 9001 systems. The work was straight forward and went without a hitch.

More of this work using CNC Milling Services Devon is anticipated for the future so the CAD drawing were filed for future use.

The client did not specify a deadline for the work to be completed. RB Engineering finished the work in 32 hours. After all the necessary inspections the mixer shaft spacers were delivered to the customer who was happy with the results.

About CNC Milling Machines

CNC stands for Computer Numerical Control which is a computer controlled high precision machine that is able to make repeated accurate movements.

Codes are taken from a computer and converted into electrical signals using software. The signals are then used to control the machines motors. The motors are able to turn at small amounts and this allows the machine to move repeated high precise movements.

CNC machines can be used for running some of the most common types of machine tools such as: drilling machines, milling machines and lathes. Using CNC machines has become very popular with UK manufactures.

CNC Milling Services – Sibelco

CNC Milling for Devon

Tags: 40mm plate, CAD drawings, CNC milling, Devon, dowels, ISO9001, lathe, mixer shaft, shaft spacer

Posted in RB News |

Comments Off on CNC Milling Services Devon

March 16th, 2015

RB Engineering received a new project request for steel fabrication at Paignton Zoo. The Zoo had designed a background theme for their latest feature Wetlands that was due to open in the summertime. This gave the team at RB Engineering a month to complete the project.

Paignton Zoo had prepared the design in an art package file which had to be converted to work in the water jet cutting software. Several meetings were held between the Zoo and RB Engineering to discuss the changes that were required before work could commence. Health and safety issues were also discussed including the rounding off the sharp points that showed in the original design to make the sculpture safe.

The client also specified that they would like to have the sculpture made with mild steel as this would give a rustic look to the piece.

Drawings were then made for the project and once they were accepted by the client an order was placed for the material. Once the material had arrived it was loaded into the water jet and cut to the required size.

The client visited RB Engineering to discuss how much roll was required on the plate. The end result had to be that the sculpture would stand on its own without wobbling. The plate was then rolled to specification.

On completion of the project the sculpture was then delivered to the site and placed in concrete by staff at the Zoo. The steel fabrication for Paignton Zoo was a success and the client and designers were extremely happy with the end result.

You can check out the work for yourself as the sculpture still stands at the entry to the Wetlands feature at Paignton Zoo.

Steel Fabrication Paignton Zoo

Steel Fabrication Paignton Zoo Wetlands Project

Tags: Design, drawing, Paignton Zoo, sculpture, Steel Fabrication

Posted in RB News |

Comments Off on Steel Fabrication for Paignton Zoo

March 9th, 2015

The task for the RB Engineering team was for mild steel fabrication in Devon. The team were requested by the client to fabricate a gas cylinder storage cage in accordance with the British Oxygen Corporations safety criteria. The time scale was 3 weeks and the finished product was to be completed and installed in time for the new college to open.

RB Engineering were familiar with this type of work and a meeting was arranged with the client to discuss the required mild steel fabrication. The team were given information regarding the amount of cylinders to be stored and that the cage would fit on a concrete plinth which had already been cast onsite. The cage was required to be primed with zinc and powder coated in red to match the trim colour of the building. A sketch was made for the mild steel fabrication in Devon.

Once the sketch was converted into to a computer model drawing it was sent to the client for approval. When the approval was received the materials were ordered for the mild steel fabrication work. The materials used were: mild steel box section, mild steel angle and mild steel mesh.

The cage was bolted together in the RB Engineering workshop where the client was invited to inspect it for suitability and security. The client was happy with the work and so the cage was dismantled and sent for off powder coating.

The parts were collected from the powder coaters and taken to the client site. Assessments were carried out for risk and method before the installation began. The cage was then re-assembled and fitted to the concrete base as required. The work was completed within the scheduled time and the customer was more than happy with the end results. The gas supplier was also happy about the storage facility for the gas cylinders.

Mild Steel Fabrication 2

Mild Steel Fabrication 3

Mild Steel Fabrication

Tags: college, Devon, Manufacture, powder coating, Steel Fabrication

Posted in RB News |

Comments Off on Mild Steel Fabrication in Devon

March 2nd, 2015

RB Engineering had a request to work on a kiln outlet exhaust modification. It was a one-off job and one that they had not done before. A designer from RB Engineering went onsite to measure up for the stainless steel manufacture of the kiln outlet exhaust.

The requested work required a design engineer to design a new kiln exhaust trunking so that it could take the used heat and duct it through the roof of the building. Once the design had been approved, it was passed to an acoustic designer who ensured that when the hot air would leave the building with the noise reduced to no more than 20db. This was due to the fact that the client’s building was housed in a residential area and previously there had been complaints from residents regarding the noise from the kiln outlet exhaust.

The component was drawn into our water jet cutting software and then reverse engineered to give a flat pattern. A profile was made from the flat plate, it was then folded and welded into shape. The kiln outlet would be manufactured from stainless steel.

RB Engineering were requested to fit the Kiln outlet exhaust onsite and so a crane was organised. Risk assessments for working at height were thoroughly carried out and an assessment and method report was required by the client.

The fitting went according to plan and there were no issues. While the engineers were on the roof the client requested that the flashings which seal the outlet chimney to the building were done.

The work was carried out on a weekend when the factory was shut down, this was at the client’s request.

From the onset of the work on the kiln outlet exhaust a combination of skills provided by RB Engineering helped to solve the client’s problem of noise pollution in a residential area.

Stainless Steel Fabrication for kiln exhaust

Stainless Steel Fabrication for kiln exhaust.

Stainless Steel Fabrication for kiln exhaust

Posted in RB News |

Comments Off on Kiln Outlet Exhaust Modifications

February 23rd, 2015

RB Engineering received a call from a client who needed help to create a perforated plate design that would stay absolutely flat. In the past it was usual for the client to order the perforated plate from a supplier but, these were usually made by laser or punched which would cause the metal to warp. This would cause a problem with a build-up of materials being used in the perforated plate. We decided to make the perforated plate using CAD software.

Damaged perforated plate

Damaged perforated plate

The perforated plate would be made from 5mm 316 stainless steel. The advantage of having this profiled and cut on the water jet is that there is no warp age of the metal as it is cut using water. The perforated plate has to be installed perfectly level so the material is always cold.

A qualified designer at RB Engineering created the drawing for the perforated plate design using CAD software. The drawing when then past to a qualified water jet cutter for profiling and creating the plate. The material was required to be cut to a tolerance of 0.05mm.

Before the work began test cutting was done using scrap material to see if having all of the holes closer together would relieve any stress in the rolling of the stainless steel causing the plate to lift. This didn’t happen so the material was ordered to begin the work on the perforated plate.

Perforated steel plate with water cutting machine

Cutting steel plate

When the work was completed it was scheduled for completion. On completion the client collected the perforated plate and it was fitted by their own staff. Once installed the customer tested the plate and informed us that it was working to their satisfaction and they were able to put a greater

put through of material.

RB Engineering had solved the problem of the perforated plate design for the customer who was more than happy with the work that the production team had carried out. This type of work will now be standard on all screen deck machines.

Tags: CAD, cutting, drawing, Perforated steel plate, Stainless Steel, Steel Fabrication, water jet

Posted in RB News |

Comments Off on Perforated Plate Design Using CAD Software

February 16th, 2015

Steel Fabrication and Maintenance Work

RB Engineering are experienced in all types of Steel Fabrication and Maintenance Work. Projects such as Roll Cages, Stainless Steel Storage Tanks, Mezzanine Floors, Stainless Steel buildings and staircases, are just some of the projects that the company has worked on.

When a client contacted RB Engineering for help with rusted trunking the work was carried out to a high standard and the client had more than one problem solved.

The hot air trunking from the furnace to a crushing machine had rusted due to condensation that was caused by constant hot and cold temperatures through the trunking. It was obvious that the trunking would need to be replaced with a material that could cope with the constant change in temperature. The materials used were 6mm thick mild steel to handle the heat and chromium content to help alleviate the condensation and prevent corrosion within the pipes.

Drawings were taken onsite and then a CAD model was made and put into our duct forming software which unfolds the drawing into a flat pattern that the water jet can follow to profile the necessary parts. MAG welding was used on this project to produce the required product for the client. All of the drawings for this Steel Fabrication and Maintenance work were filed for future reference.

The installation was completed on the client premises at an arranged date, and although the work had taken time to complete because of the complexity of the drawings the client was more than happy with the product.

Hot Air Trunking Repair

Hot Air Trunking Repair

The expertise and skill of Steel Fabrication and Maintenance Work offered by RB Engineering helped to provide a first class, longer lasting product for the client.

Tags: CAD, Design, drawing, Maintenance, metal fabrication, Stainless Steel, Steel Fabrication

Posted in RB News |

Comments Off on Steel Fabrication and Maintenance Work

February 9th, 2015

Roll Cage Manufacture and Design

As a bespoke manufacturer RB Engineering are involved in many different types of projects including roll cage manufacture. This type of project requires specialist skills in the design, welding and the construction of the roll cage.

When an email arrived at the office with a request for a certified roll cage to be fitted to a 50 series x army dodge pickup, the job was picked up by our experienced engineer. The work would prove to be relatively straight froward to do as this type of project is common place at RB Engineering. .

Roll Cage before

The customer requested a simple hoop design to fit behind the cab and 2 back stays were also required. It was important that no space was restricted from the load bed of the vehicle.

The materials used for the project of roll cage manufacture consisted of 90mm of cold drawn seamless tube which was MIG welded to base plates. All of the welded joints were done to the standard of EN51614-1-2012. Cross members were designed to go across the vehicles chassis to allow the roll cage to be bolted on.

Once the vehicle had arrived in the workshop, the chassis cross members and attachment plates were mounted. A CAD drawing was then produced for the tube bending layout and the programme was put into the tube bender machine.

2 back stays were then cut and the tube was then notched to the correct radius. Using a MAGS welder the stays were then welded to the hoop and the attachment plates were welded to the bottom of the back stays.

Roll Cage After

On completing the work the roll cage was duly rubbed down and primed with etch primer then painted with 2 coats of black top coat

A full inspection was carried out on the roll cage before the vehicle was returned to the customer.

This roll cage manufacture project is just one of the many various project services that RB Engineering provide for their customers.

If you need a high quality roll cage, get in touch!

Roll Cage Fitted

Roll Cage Design

Tags: CAD, Design, Fabrication, Manufacture, metal fabrication, Roll Cage, Tube

Posted in RB News |

Comments Off on Roll Cage Manufacture and Design

February 2nd, 2015

Stainless Steel Repair Devon

During our work with clients it is often the case that time is of the essence for having work completed in the shortest time possible without compromising quality. Good planning and customer communication play an important part in achieving an agreed timescale. A prime example of this was when a client called in with a problem they had for unloading bulk materials from a hopper. The hopper was in a bad state, it was very rusty and riddled with holes and it was certainly passed its ‘sell-by date’.

The time scale was very imported as our client was expecting a bulk tanker to arrive and be filled up from the hopper and delivered to their next customer. We had a six hours to complete the work which included stripping out the chute and fabricating a new one using Stainless Steel. It was imperative that the work was completed as soon as possible.

Before beginning the work we were supplied with a drawing. RB Engineering produced an in house CAD drawing for the top flange for water jet cutting, and then went on to complete a drawing for the whole item.

The materials we used for the work was 6mm Stainless Steel flat sheet which was rolled into shape in house with our hydraulic pyramid rollers. The mounting flange was profiled on our water jet cutter from 10mm Stainless Steel, it was then welded together using our synergic mag welding machine. Once the work was finished it was delivered and fitted onsite for the client. The process from start to finish took five hours to complete.

Throughout the time the work being carried out, communication between our client and ourselves was frequent. This helped to ensure that the client had a good insight as to how the work was progressing.

With hard work and efficiency the job was completed to a high standard and well within the essential time frame and our client was able to make the delivery to their customer in time.

Stainless steel repair – Before

Stainless steel repair – After

This is just one example of the many client stories we have to share with you. Here at RB Engineering we carry out this type of work on a regular basis and pride ourselves on our quality of work and our relationship with our clients.

Tags: CAD, drawing, fabricating, flange, hydraulic pyramid rollers, metal fabrication, Stainless Steel, water jet cutting

Posted in RB News |

Comments Off on Stainless Steel Repair Devon

July 13th, 2014

RB Engineering is a bespoke manufacturer involved in many different engineering projects and roll cages and metal fabrication is just one of them. There are no projects too small, too large, or too specialized, and we cover everything from steel fabrication, water jet cutting, marine fabrication, and rollers and conveyors. If you’re a fan of Rally sport racing, you may have even seen some of our work in action; we have manufactured roll-cages for a number of popular rally cars. If rallying isn’t your thing, you may be wondering what a roll-cage is? A roll cage is the single most important safety feature in the car, and it’s not something that you would trust to just anybody. If you crash and your roll-cage fails, that’s it – game over. If you consider yourself a cinephile, you may have seen Quentin Tarantino’s Grindhouse, and in particular, the feature Death Proof where Kurt Russel kills his victims in staged car crashes, while protecting himself in his roll-cage equipped stunt-car.

Metal Fabrication Specialists RB Engineering

Constructing a roll cage takes expertise in design, construction, choosing the right materials, and welding. Most people may not realize it, but welding is an art in itself. There are many different types of welds, depending on the materials being used. RB Engineering has experience and expertise in all the different types of welds, which are MIG, TIG, MMA, and 450 amps. What exactly are these different weld types? MIG stands for Metal Inert Gas, and is also sometimes called Gas Metal Arc Welding, or GMAW. This process was developed back in the 1940’s to weld Aluminum. The process initially used an inert gas like argon. Argon is one of the so-called “noble” gasses, characterized by their properties, which are colorless, odorless, monatonic, with very low chemical reactivity. Although argon is the third most abundant element in the earth’s atmosphere at 0.93% (even more so than carbon dioxide), it is expensive, which meant that MIG welding was a relatively expensive process. Relatively recent advances in the technique enabled the use of semi-inert gasses like carbon dioxide, which saw a significant drop in the cost of this weld technique, opening it up to a host of other applications, including welding steel which is now cost-efficient.

So what are the advantages of MIG welding over other types of weld techniques? For one, we’ve already mentioned its ability to weld non-ferrous metals like aluminum, which it was originally designed for. Its other advantages though, are what make the technique useful in steel welding for instance. These are:

- MIG welds produce long, continuous welds much faster than a normal, or traditional weld.

- The technique produces a clean weld with very little “splatter”, thanks to the protection offered by the shielding gas.

- Finally, the technique can be used in a wide variety of metals and alloys.

Welding of all metals

So then the question arises. If MIG welds have so many advantages, why are we all familiar with the more “traditional” welding techniques? If MIG has been around so long, why isn’t it more widespread and better known? This brings us to look at the disadvantages of the technique.

- MIG welding equipment is complex and expensive. You need a source of direct current, a continuous stream of gas, and a continuously moving wire electrode. The electrode itself varies in size and type of metal, and has to be matched to the specific welding application.

- Even welders that are experienced in traditional welding need some time to get the hang of it.

- The use of the inert gas shield means that the technique cant be used in open areas where even a light breeze would blow the gas away. In cases like this, special measures need to be taken to prevent this from occurring.

Posted in RB News |

Comments Off on Roll Cages and Metal Fabrication

July 3rd, 2014

Steel is the most popular construction materials, and for good reason. It’s being used more and more in construction lately, from the humble agricultural sheds, to the world’s tallest skyscrapers. So what are its advantages? Some of these are:

• Steel is durable, cost efficient, and easy to work with.

• Steel can be manufactured to tight tolerances.

• Steel, once manufactured to correct specifications, is easy to install.

• Steel is a very cost effective material, and global prices are relatively stable.

• Steel requires less maintenance.

• Steel has excellent safety features.

British Ceramic Tile’s Steel Platform and Staircase

We’ve seen why someone would want to construct with steel. Now, what possible difference could it make who your partner is if you decide to construct a steel building? Lets take an easy scenario. In its simplest form, steel manufacturing involves the construction of beams and columns for erection on the building site. These beams and columns are delivered with welded flanges and pre-drilled holes ready for assembly. This all sounds simple and straightforward, but what isn’t evident is all the work and planning that goes on behind the scenes. The beams and columns have to match up perfectly when delivered, for obvious reasons. A building site may appear to be chaotic, but everything happening there has been perfectly planned, down to the last detail. For instance, the right materials must be delivered just in time, when needed, so construction can proceed smoothly. If they are delivered early, there may be no storage space to put them, and they may restrict movement on the construction site by being in the way. Delivering materials late is just as bad. Workers sit idle, heavy lifting machinery that was hired for the job of hoisting the materials into place sits idle and rental costs accumulate. Even worse, the machinery may have been rented to another project on a tight schedule and may have to be moved before assembly can be completed. That can lead to huge project delays, cost overruns, and lawsuits. Worse than a lawsuit, is the reputational damage that can be suffered by all parties.

Steel Fabrication in Newton Abbot and Devon

So, you can see why it’s so important to be reliable in this type of business. That’s why RB Engineering works closely together with its clients, manufacturing to our well-known tight tolerances, using quality materials, tracking what is being manufactured, labeling all parts correctly, and ensuring that deliveries are on time.

So how exactly do we do it? We’ve already seen in our other online articles that we accept CAD files directly from our clients, which they can upload directly on our web site. Using the client’s own files, which can be in any of the well known formats including DWG, IGS, CADKEY, CDL, HPL and DXF, we can use our own CNC enabled machinery to produce quality results. What types of projects have we taken on? We have experience constructing stainless steel storage tanks, mezzanine floors, steel buildings and staircases.

To the casual reader, these projects may seem like straightforward affairs, but in reality, each has its own hidden complexity. For instance, storage tanks may have many different uses. Specialty tanks are needed depending on whether it is intended for dry bulk, energy and power, construction, or some other application. Mezzanine floors may be intended for a variety of uses, like manufacturing, office space, or storage. Steel buildings can be used for agricultural storage sheds to high-rise office buildings. Every application has its own intricacies, which is where experience and reputation comes into its own.

Posted in RB News |

Comments Off on Steel Fabrication in Newton Abbot and Devon

June 30th, 2014

Waterjet cutting almost seems like an contradiction in terms. Especially when you realize that we are talking about cutting high-grade steels and alloys up to 20cm thick. To put that into context, modern ships have hulls that are 17 – 19 mm thick. How is it even possible for a stream of water to cut through some of the toughest alloys known to modern science, and when was this process invented?

Waterjet technology has actually been around for some time now and at RB Engineering we are the experts. The first recorded use of high-pressure water as a tool was in Roman times, when hydraulic mining was used to excavate soft underground deposits. A more modern form of this concept was developed in the late 1800’s using water jets, again used in mining. Although efficient in excavating gold deposits, this technique was an environmental disaster, resulting in extensive erosion and flooding and was later banned. Later on, in the 1930’s, water jets were used to cut paper, and in the 1950’s, the technology was improved to allow the cutting of plastic. It was only in the late 1950’s that the waterjet technology we recognize today came into existence. In 1958, Billie Schwacha of North American Aviation developed a system, which produced an ultra high-pressure stream of 100,000psi, capable of cutting hard materials. This technology was used on the XB-70 Valkyrie, a six-engine, mach 3 strategic bomber which was a Concorde lookalike of its day. So we can safely say that modern waterjet technology was born to serve the needs of our modern aerospace requirements.

Today’s waterjets have since been refined and improved beyond recognition since their debut. Nozzles have been improved to produce a much finer stream, cutting to specifications of up to five-thousandths of an inch tolerance. And although water pressure has been reduced, typically between 20,000 and 50,000 PSI, the water is forced through a fine nozzle about 0.010” to 0

.015” in diameter, producing water speeds reaching mach 3. Unlike metal cutters, a waterjet will never overheat, its blade will never dull, snap, or otherwise become damaged at a critical point in a project. The cutting process is so fine, that polishing will likely never be required, and waste will be minimal to non-existent.

So in summary, what are the advantages of using a waterjet to cut materials? Lets start off by summarizing what we can cut using this high-tech method of cutting.

- Aluminum

- Brass

- Bronze

- Copper

- Titanium,

- Steel (mild, hardened, high alloy, tool and stainless)

- Hastaloy

- Tungsten

- Zirconium Composites

- Foam

- Glass

- Granite

- Marble

- Plastics

- Rubber

So now we know that this tool can cut through practically any material, what makes it better than any other high-tech cutting solution? Lets compare waterjets to laser cutting.

|

Laser |

Waterjet |

| Appearance of the cut surface |

The cut surface will show a striated, or streaked structure, which will need further attention. |

Depending on the speed of the cut, the appearance of the cut surface will seem to have been sandblasted. |

| Processing tolerance |

Approximately 0.002″ |

Approximately 0.008″ |

| Burring on the cut surface |

Partial burring occurs |

No burring occurs |

| Effect of thermal stress on the cut material |

Heat deformation, tempering and structural changes may be present in the material |

No thermal stress occurs, as this is a cold process. |

Surprisingly, a waterjet can cut within tolerances of five-thousandths of an inch, in an odorless, heat and dust free (but unfortunately, not noise-free) manner. By cutting to such fine tolerances, materials are produced with a single-cut process, minimizing, time, materials, labor, and cost, with the first cut giving the quality of a final finished surface. The fact that the process is thermal free means that we need not worry about allowing for deformation of our end product, allowing us to work with ever tighter tolerances and a more attractive end result.

Posted in RB News |

Comments Off on Waterjet Cutting in Devon

June 18th, 2014

Abrasive waterjet cutting has many benefits over conventional profiling methods. Waterjet Cutting Services Newton Abbot

waterjet-cutting

• No heat affected zones – it is a cold process.

• No tool contact, therefore no edge deformation.

• Materials from thin shim to 200mm thick can be profiled.

• Virtually any material can be cut.

• Substantial material savings because the cutting tool is only 1mm wide.

• Clean, accurate process.

• No tooling costs.

• Computer ‘nesting’ of parts maximises material utilisation.

• Secondary cleaning operations are reduced or eliminated.

• No restriction on hole sizes.

• Little or no burr.

• Extremely detailed geometry.

• Very little side force is placed on the material whilst cutting, allowing delicate parts to be cut.

Waterjet cuttting

Posted in RB News |

Comments Off on Waterjet Cutting Services Newton Abbot

June 16th, 2014

A client wanted a new platform and staircase to be constructed they called on RB Engineering to carry out the task.

Our client is a UK manufacturer of ceramic tiles, based in Heathfield Devon, and just a stone’s throw away from RB Engineering. Our client is the largest and most efficient tile making plant on one site in Europe and is capable of producing 30,000 m² of tiles per day, which accounts for 20% of the market share of the UK tile market.

Steel Platform and Staircase

RB, engineering, were asked to produce a new platform and staircase to the Heathfield-based company.

Tags: metal fabrication, metal staircase

Posted in RB News |

Comments Off on Steel Platform and Staircase Fabrication

May 13th, 2013

We would like to welcome Clive Whittle to the team here at RB Engineering. Clive will be our new account manager looking after our existing client base as well as introducing new clients to the business.

Posted in RB News |

Comments Off on Clive Whittle joins RB Engineering

May 3rd, 2013

We are extremely proud to have been asked to manufacture the new ‘Light Bulb Moment’ for Exeter college who have just completed their 9 million pound new engineering department. The ‘light bulb’ was designed by Eleanor Tucker, a student at Exeter College studying Art and Design.

Posted in RB News |

Comments Off on Light Bulb Moment!

March 7th, 2013

We have seen a steady increase in the production of Conveyor Rollers over recent months. We are able to manufacture or Repair Conveyor Rollers in any specification and provide a nationwide fast turnaround service.

Posted in RB News |

Comments Off on Increase in production of Conveyor Rollers